INTRODUCTION

Except where specifically indicated, the statements and information set forth in this Whitepaper are not intended to recite current or historical facts, and constitute forward looking statements. Forward-looking statements may include the words “may,” “will,” “could,” “should,” “would,” “believe,” “expect,” “anticipate,” “estimate,” “intend,” “plan” or other words or expressions of similar meaning. These forward looking statements are based on the current beliefs, plans, objectives, goals, expectations, anticipations and/or intentions of MOXY OID with respect to future events. Although MOXY OID believes that the expectations reflected in the forward looking statements are reasonable, MOXY OID cannot guarantee the successful establishment or operation of its systems and business or any future results, level of activity, performance or achievements.

Many factors discussed in this Whitepaper or otherwise affecting the matters discussed herein, some or all of which ma y be currently unknown to MOXY OID or beyond MOXY OID’s control, will be important in determining the ability of MOXY OID to establish and operate its systems and business. Consequently, actual results may differ materially from those that might be anticipated from the statements and information set forth herein. In light of these and other uncertainties, the statements and information set forth in this Whitepaper are for informational purposes only, should not be relied upon in making any purchase or other decision, are subject to change, and are not intended to establish or indicate any representation, warranty, commitment, undertaking, promise or contract made on the part of MOXY OID to any person. MOXY OID does not undertake any obligation to publicly update any forward-looking statements, whether as a result of new information, future events or otherwise, except as required by law.

EXECUTIVE SUMMARY

MOXY OID is set to fundamentally change the near trillion-dollar building materials market with its Trade Secret - sustainable and ultra-high- performance products branded as CERLOS. Our CERLOS products have the following qualities;

Fire-resistant, achieving a Class A fire rating.

Termite, insect, rodent and bird resistant.

Mold resistant.

Water-resistant and all-weather stable, won’t shrink or swell.

It can be cut, machined, drilled, and otherwise worked in the field.

It can be molded to almost any shape in manufacturing.

MOXY OID is headquartered in Vancouver, BC, Canada, and utilizes proprietary technology to address a real need in the Global building material marketplace. The company intends to manufacture highly marketable building products and is expecting to reach annual sales of USD$643 million by the seventh year of operation. In 2016, USD$28.9 billion in damages were caused by building fires, insects like termites and floodings, when most of the losses were preventable. Meanwhile, construction materials around the world are not recyclable at the end of their lifecycle and deemed hazardous waste. Every day 80,000 ACRES of forests disappear either form wildfires or through logging to create wood products and building materials.

MOXY OID answers the markets’ demand for innovative and sustainable building materials. The composition and properties of CERLOS products contribute to the higher profitability of MOXY OID while being sustainable and environmentally friendly.

CERLOS can be described as a new, engineered wood product utilizing 100% natural ingredients with no chemical additives, unprecedented aesthetic possibilities, and excellent handling characteristics.

CERLOS products have a unique advantage over competing, traditional products by the unlimited supply/origin of the raw materials used in its manufacturing. Furthermore, the combination of its properties, and the fact that at the end of each cycle use, the product can be recycled (cradle to cradle).

In addition, in almost all cases CERLOS products are superior in performance to comparable products at a price point equal to or less expensive than their comparable. CERLOS products are made in an environmentally responsible way. Our proprietary, low-cost, low-energy process converts wood fibers and agricultural residues into high-performance building products for green building.

MOXY OID is at a pivotal point, shifting from $22.5 million in R&D to an operating profitable company by commencing manufacturing of its market entry product, CERLOS Siding/Cladding.

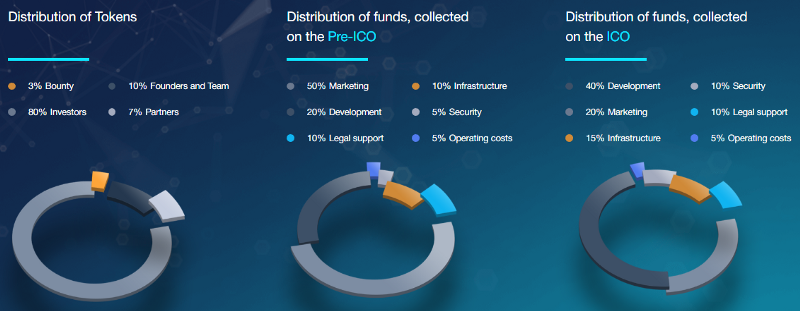

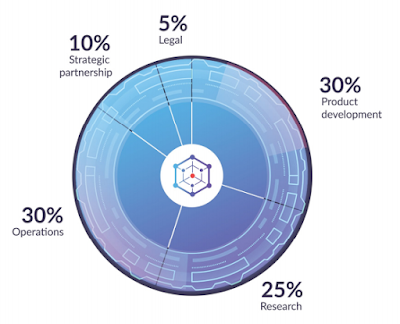

The majority of the fund (60%) will be used by MOXY OID to build a High capacity manufacturing facility in the Pacific Northwest, in North America to meet the demand for CERLOS products. Legal, Business Development and Administrative expenses will use 10% of the funds raised. Marketing and Business Development will use 10%. Research and Development will be allocated 10% of the funds raised while the balance 10% is allocated to take care of the issue and fund raising related expenses.

CERLOS Inc is raising US$20,800,000 through an IEO, offering an Asset-Backed Token to acquire 25% equity stake in MOXY OID which is the Canadian Operating company belonging to the same group. By virtue of this investment, the Token Holders of CERLOS Inc will receive 90% of the dividends earned by CERLOS Inc. The token offering is facilitated by CGCX.io exchange where the tokens will also be listed and traded subsequent to the offer.

OUR VISION AND VALUE PROPOSITION

MOXY OID will become a global supplier of sustainable building products, initially accelerating High-Capacity manufacturing operations in North America, followed by Europe, Latin America, and Asia-Pacific.

MOXY OID’s market launch product line will be siding/cladding/fascia, followed by roofing products, and then panel boards, displacing competitive, yet inferior, plywood, oriented strand board (OSB), mediumand high-density fiberboard (MDF/HDF) and other engineered wood, fiber cement, plastic MgO boards, and other composite products including drywall.

To improve the quality of life physically, financially, and environmentally by providing a costeffective eco-friendly building material that is fire, mold, rot, and insect resistant.

OBJECTIVES

MOXY OID’S OBJECTIVES ARE:

Patent applications.

Select a site for establishing a high capacity manufacturing facility in the Pacific Northwest. The site should have rail and road transport access. The facility should be 60,000 to 80,000 square feet with a surrounding area of 10 to 20 acres to accommodate materials in and out. Initially, we prefer to lease the property and buildings.

Using traditional media to market CERLOS products to the building material community.

Use influencer marketing to bring CERLOS products to the attention of home and building owners.

Introduce the CERLOS Certified Representatives program with the intent to create a strong regional and national salesforce that is trained to use and promote CERLOS products.

PROBLEMS AND SOLUTION

There are severe ecological and economic problems associated with the existing building materials in terms of their properties, input ingredients that are used to manufacture them, the manufacturing process itself, and their environmental impact.

MOXY OID tackled and solved these problems one by one in the span of 18 years of research and development, with more than $22 million spent. The result is our revolutionary building material CERLOS.

CERLOS products are fire, insects/bird/rodent, rot and mold resistant, water and all-weather stable (will not shrink or swell), or decay or are influenced by environmental hazards. MOXY OID manufactures superior performance, sustainable, energy efficient, and cost-effective building materials that install easily with conventional carpentry tools. MOXY OID’s manufacturing processes are environmentally responsible and petroleum-free, addressing market needs for building “green.” Their products are designed to meet the most stringent testing requirements of the industry and demonstrate superior performance in all key attributes.

The building materials industry suffers from technology stagnation, and not a lot has happened in building materials over the past 50 years. One may remember OSB (oriented strand board) some 30 years ago was flaky and fell apart easily. Today, it does not. Why? Well, one of the few things that have improved with engineered wood materials is the resins (glue). However, their unfavorable characteristics, such as being easily flammable, prone to shrink, swell, rot when wet, and easily damaged by insects, rodents, and birds remain constant.

Other products like fiber cement have been developed, but being 85% to 90% by volume Portland cement, they are cement, act like it, and require cement tools. Fiber cement products are brittle and are adversely affected by moisture, freeze/thaw. Cement is corrosive on metals and requires noncorrosive, galvanized or stainlesssteel cladding nails. But if not for the reasons referenced above, fiber cement contains silica dust, a known carcinogen (cancer-causing agent). The health and welfare of the installers who are rarely seen taking any precautions from the silica dust are at great risk.

Like fiber cement, magnesium boards (mag-board or MgO board) perform better than fiber cement but tend to be a little more expensive than fiber cement, and is a hygroscopic product, known to produce a problem named “crying boards” when applied in a very humid climate. Newer plastic products have also been developed, like Wood-Plastic Composites (WPCs), that are produced by thoroughly mixing ground wood particles and heated thermoplastic resin. Sustainable/ Eco- Friendly?

Certainly not in our view.

MOXY OID DELIVERS SOLUTIONS

After over 18 years and US$20 million spent on Research and Development, we have developed a brand new building material that addresses many problems associated with current building materials. CERLOS solves the following issues:

SUSTAINABILITY :

Unlike other building materials, CERLOS is created using 100% sustainable methods and can be 100% recycled after use to make brand new CERLOS.

DURABILITY :

CERLOS products are fire resistant, insect/bird/rodent resistant, rot and mold resistant, water and all-weather stable (will not shrink or swell), or decay or be influenced from environmental hazards.

ECO-FRIENDLY :

Our primary ingredient is lignocellulosic fiber. Lignocellulosic fiber is basically the cells of virtually all living plants, so the fiber can come from straw, cornstalks, or from any other agricultural or forestry waste.

COMPANY AND TECHNOLOGY DEVELOPMENT HISTORY

Following 18+ years of R&D and approximately $22M in R&D investments, a combination of ingredients and procedures resulted in the remarkable new building material, CERLOS. It all started with Alan Heywood in 1985, co-founder of MOXY OID and inventor of CERLOS. The technology and process knowledge were developed from a combination of several intellectual properties. The primary discoveries that triggered the start of the search for a new composite building material were published in the 1960s and ’70s. Mr. D.A. Alan Heywood, working off those publications tenaciously performed in-depth research, development, and testing of ingredients, formulas, and processes. Alan purchased a patent from Dr. Laszlo Paszner and formed C-Max Technologies International Inc. The patent had good prospects but failed in every attempt to produce any quality samples Research and development continued for 16 years until 2002 with $8+ million of funding and $4 million in-kind contributions as testing equipment and a laboratory by MacMillan Bloedel5 between 1994 and 1997. Good fortune comes to those prepared to work to find solutions, and ultimately, solutions were found. Alan develops CERLOS after numerous testing of formulations and many years of research.

In the following years, $1 million spent on research and design, a preliminary manufacturing line was prepared as a result of the engagement with Corvallis Tool Company of Oregon, OR 97370. Corvallis specializes in the design, engineering, manufacturing, installation supervision and startup of custom industrial machinery and control systems for a wide variety of wood product manufacturers. In January 2012 and with $2 million in funding, MOXY OID Technology Management LTD was incorporated to aid in the management and commercialization of the technology. A $7 million, four (4) year design, engineering, and development program was commissioned between 2012 and 2017. The program resulted in several proprietary processing steps with unique equipment for a large-scale Pilot Plant production facility and validated commercial quality and quantity for CERLOS production. The Pilot Plant was built in Holland with VDL Enabling Technologies Group, an engineering and equipment manufacturing firm. This extensive information will be used in the High-Volume manufacturing line. For the period of 2018 to 2019, MOXY OID is in preparation and development of websites, corporate documents, legal documents, and requirements for the funding of a High- Volume manufacturing facility.

CERLOS IS ORGANICALLY CHANGING THE BUILDING MATERIALS INDUSTRY

Our new construction material to date has been successfully tested in a vast array of different forms of structural and value-added building products. In each and every case, improvements were made in economics and end-product quality. CERLOS products demonstrate many profound and dramatic characteristic improvements over the products that are currently in use. A product having the improved characteristics of this new technology presents a worldwide opportunity, and to date, no evidence of any other company or research organization proclaims to have discovered anything close to this new material. The ratios of the ingredients within the blends or formulate vary by design according to the required end-product specifications. These improved characteristics are achieved by a natural, environmental process called Mineralization, which is when organic fiber is strengthened as the porous gaps in the fibers or cells are filled in. This process can occur naturally under certain conditions resulting into petrified wood or fossils and can also occur biologically with the formation of our bones, egg shells, teeth or coral.

MOXY’s breakthrough is the development of a controlled mineralization process of plants and trees that provides an inexpensive material strengthened through a natural process. Part of the breakthrough is the manufacturing process itself.

Examples of Natural or Biological Mineralization:

Teeth : Teeth are the mineralized enamel and dentine cells.

Petrified Wood : Petrified wood is a common mineralization of wood.

Shells : Any exoskeleton is the result of a mineralized process.

Fossils : Fossils are often the mineralization of bones.

MANUFACTURING

A total of $7 million dollars in developing a proprietary manufacturing process was completed in a Pilot plant in Holland with VDL Enabling Technologies Group. The main benefits of the proprietary MOXY OID process during manufacturing are lowpressure forming and rapid low-energy curing. Additional benefits such as zero waste and zero discharge are inherent in this safe manufacturing process.

Economically, this fast curing, continuous low-pressure process system requires a very low capital investment per manufacturing line when compared to all other competitive manufacturing facilities. It is also important to note that MOXY OID’s unique proprietary processes have the flexibility in manufacturing to make more than just solid flat products. The benefit of this is that by altering density in products a lower manufacturing cost can be achieved by reducing the input ingredients and also grant the flexibility to create almost every construction product with CERLOS.

SIDING/CLADDING I BEAMS

- ROOFING TILE

- SHEATING

- I BEAMS

- LAMINATES

- PIPE POLES

- TRIM

- LAMINATED STRUCTURES

- BLOCKS

- POSTS

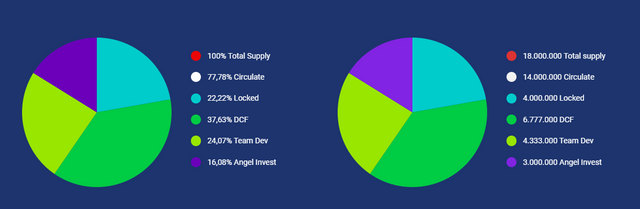

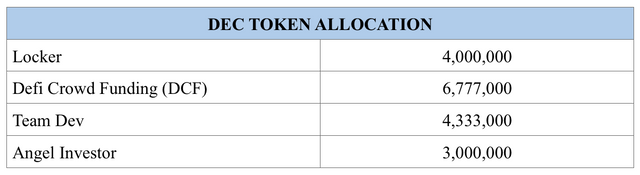

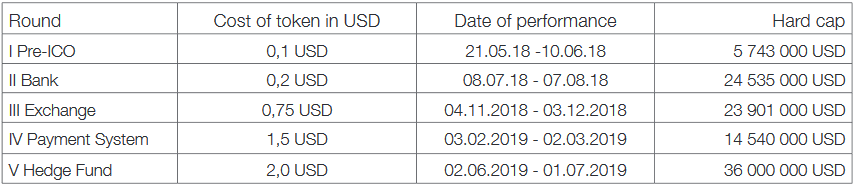

TOKENOMICS

- TOKEN NAME : CERLOS

- MINIMUM GOAL : $2,000,000

- FUNDRAISING GOAL : $20,800,000

- TOKEN SUPPLY : 25 MILLION TOKENS

- NOMINAL TOKEN PRICE : $1

- JURISDICTION : Labuan - Malaysia

- ASSET CLASS : Asset Backed Token

- INVESTORS RIGHT : Right to receive income linked to profits

- ACCEPTED INVESTMENT CURRENCIES : Bitcoin, Ethereum, USD, Euro, GBP

- ETHEREUM PLATFORM

CERLOS tokens will be issued on the Ethereum blockchain under the ERC1400 standard. Ethereum is a global, open-source platform for decentralized applications. On Ethereum, you can write code that controls digital value, runs exactly as programmed, and is accessible anywhere in the world. Launched in 2015, Ethereum is the world’s leading programmable blockchain. Like other blockchains, Ethereum has a native cryptocurrency called Ether (ETH). ETH is digital money. Like Bitcoin, ETH has many of the same features. It is purely digital and can be sent to anyone anywhere in the world instantly. The supply of ETH isn’t controlled by any government or company - it is decentralized, and it is scarce. People all over the world use ETH to make payments, as a store of value, or as collateral.

But unlike other blockchains, Ethereum can do much more. Ethereum is programmable, which means that developers can use it to build new kinds of applications. These decentralized applications (or “dapps”) gain the benefits of cryptocurrency and blockchain technology. They can be trustworthy, meaning that once they are “uploaded” to Ethereum, they will always run as programmed. They can control digital assets in order to create new kinds of financial applications. They can be decentralized, meaning that no single entity or person controls them. Most of these decentralized applications use utility ERC20 tokens. Utility tokens represent access to a network, and your token purchase represents the ability to buy goods or services from that network — kind of like purchasing a game token being used to play an arcade machine. Utility tokens give you that same type of access but just to a product or service.

ERC20 is a protocol standard that defines certain rules and standards for issuing tokens on Ethereum’s network. In ‘ERC20’, ERC stands for Ethereum Request For Comments, and 20 stands for a unique ID number to distinguish this standard from others. Similar to the fact that we have an HTTP protocol for the internet, we have a standard protocol for tokens to be issued on Ethereum i.e. ERC20. A big majority of tokens are created using it but with the new wave of tokenization of assets, this standard became an issue. It basically doesn’t comply with all intricate regulations of securities which are much more regulated financial instruments than utilities. It became a sensitive subject in the US and pushed crypto space to find new ways of being compliant with financial regulators. In response to the issue, ERC1400 standard was created. What is exactly ERC1400 token standard and why is it so important in regards to security tokens.

ERC1400 -THE SECURITY TOKEN STANDARD

Security tokens are designed to represent complete or fractional ownership interests in assets and/or entities. The most important thing about ERC1400 token standard is the fact that it has mechanisms to restrict its usage based on identity, jurisdiction and asset category. It assigns ownership to its holder — it can easily replace paper shares as it is designed on the blockchain that brings significant transparency.

Now, with ERC1400 we can make all kind of restrictions:

- Regulate holding period in a wallet.

- Whitelist all potential buyers/sellers.

- KYC wallets and restrict sales when KYC expired.

- Put a threshold on transactions.

- Limit the number of tokens per wallet.

ALLOCATION OF FUNDS

The majority of the fund (60%) will be used by MOXY OID to replicate the success of pilot project in other locations at a much larger scale to meet the demand for CERLOS products. Legal, Business Development and Administrative expenses will use 10% of the funds raised. Marketing and Business Development will use 10%. Research and Development will be allocated 10% of the funds raised while the balance 10% is allocated to take care of the issue and fund raising related expenses.

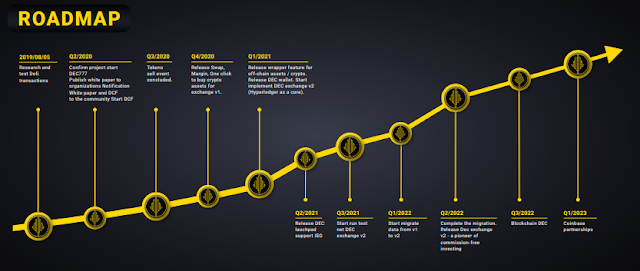

ROADMAP

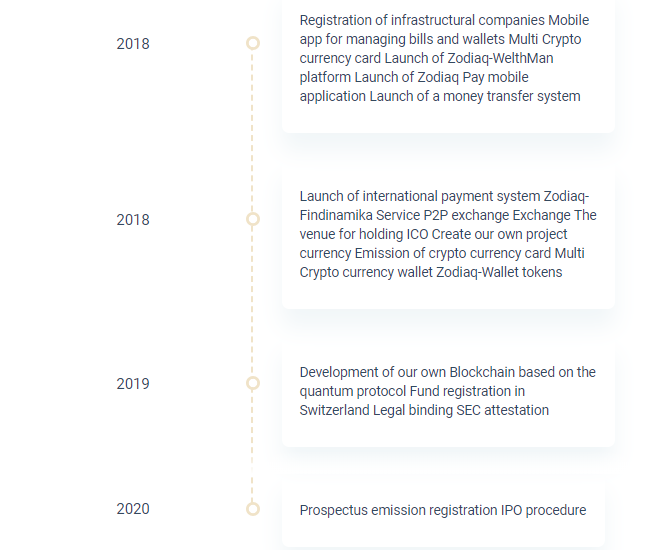

1985 : Alan Heywood (President & CTO) purchased a patent and formed C-Max Technologies International Inc.

1986-2002 : Lab research and testing. The IP is developed. $12 million spent on R&D.

2002 : C-Max Technologies is dissolved. Alan develops the technology as a sole proprietor.

2003-2008 : Alan continues to research, focusing on sources of ingredients and process equipment. Engagement with Corvallis Tool Company of Oregan to design and manufacture a preliminary design. Further $1 Million is spent on R&D.

2010 : MOXY OID is established to aid the management and commercialization of the technology. Cost: $2 Million.

2012-2017 : Pilot Plant process facility is built in Holland by VDL Enabling Technologies group. High-volume production validated. $7 Million spent.

2018-2019 : Preparation and development of websites and documents for funding of high-volume manufacturing facility and legal requirements. Cost is $500k.

March 2020 : Pre-Sale Starts

First Quarter 2020 : Begin High-Capacity design/build of manufacturing line

Second Quarter 2020 : Canada/US Site Selection

Second Quarter 2021 : First Employment of High-Capacity of 450 million ft2 per year in North America.

ACCURATE INFORMATION

AUTHOR

Telegram Username: @ dhewio8

Bitcointalk url: https://bitcointalk.org/index.php?action=profile;u=894088

Wallet address (eth): 0x53D1Ea8619E638e286f914987D107d570fDD686B